Product Description

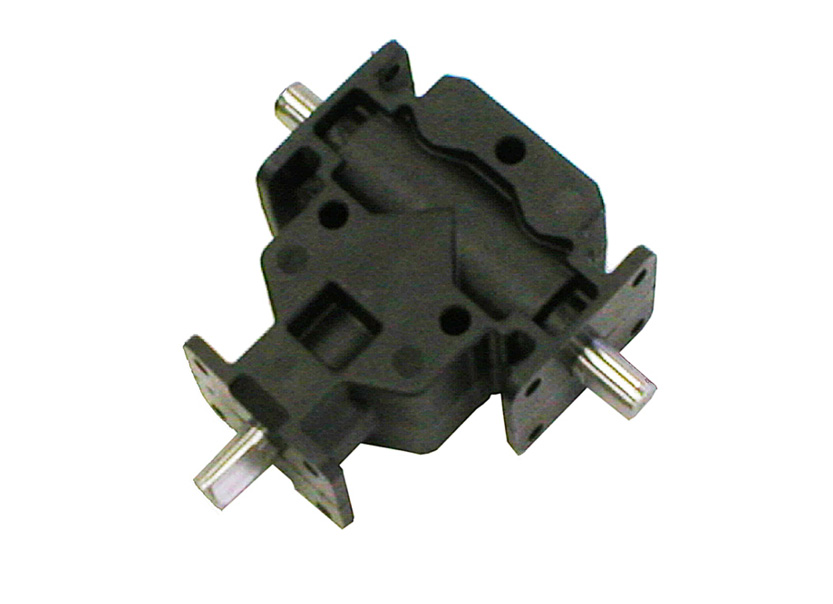

Z series hardened cylindrical gear reducer gearbox

Products Description

Single stage:

ZDY80, ZDY100, ZDY125, ZDY160, ZDY200, ZDY250, ZDY280, ZDY315, ZDY355, ZDY400, ZDY450, ZDY500, ZDY560;

Two stage:

ZLY112, ZLY125, ZLY140, ZLY160, ZLY180, ZLY200, ZLY224, ZLY250, ZLY280, ZLY315, ZLY355, ZLY400, ZLY450, ZLY500, ZLY560, ZLY630, ZLY710;

Three stage:

ZSY160, ZSY180, ZSY200, ZSY224, ZSY250, ZSY280, ZSY315, ZSY355, ZSY400, ZSY450, ZSY500, ZSY560, ZSY630, ZSY710.

Four stage:

ZFY180, ZFY200, ZFY224, ZFY250, ZFY280, ZFY320, ZFY360, ZFY400, ZFY450, ZFY500, ZFY560, ZFY630, ZFY710

Z series Hardened cylinder gear reducer is in accordance with the the PRC Professional Standards

(JB/T8853-1 999) production, the main products is ZDY (single-stage),

ZSY (three) 3 series for metallurgy, mining, transportation, cement, construction, chemical, textile, light industry, energy and other sectors of mechanical transmission.

Z series hardened cylindrical gear reducer

Speed reducer shaft speed n1, ≤ 1 500r/min.

Reducer working environment temperature -40 ~ 45 ° C. Below 0 ° C, the oil should be preheated before starting.

Reducer main work characteristics

(A) gear with high strength carbon steel hardened by carburizing made tooth surface hardness of P {RC54 ~ 62:

(2) gears grinding process, high precision and good contacts:

(3) high carrying capacity, than the soft old tooth surface reducer carrying capacity increased sevenfold:

(4) high transmission efficiency, single-stage up to 98%, 96% two, 3 up to 94%:

(5) long life.

Scope is as follows:

1, ZDY / ZLY / ZSY hardened cylinder gear reducer shaft revolution speed of not more than 1500 rev / min.

2, the gear transmission peripheral speed of not more than 20 m / sec.

3, the working environment temperature -40-45 ° C, if less than 0 ° C, before the start of oil should be preheated to above 0 ° C, the gear unit can be used for both positive and negative direction.

Product Features:

A gear made of high strength carbon steel hardened by carburizing made tooth surface hardness of HRC58-62, gears are used CNC grinding process, high precision, good contact.

2, the transmission rate is high: More than 96.5% single-stage, two-stage greater than 93%, 3 more than 90%.

3, smooth operation, low noise.

4, small size, light weight, long life, high carrying capacity.

5, easy dismantling and easy to install.

Reducer models, specifications and representation methods:

Model:

ZDY / ZDZ single-stage cylindrical gear reducer;

ZLY / ZLZ 2 cylindrical gear reducer;

ZSY / ZSZ 3 cylindrical gear reducer;

ZFY 4 cylindrical gear reducer.

Technical data:

Gearing Arrangement: Bevel / Miter

Output Torque: 450~130000N. M

Rated Power: 5~6666KW

Input Speed: 750~1500r/min

Output Speed: 134~1200r/min

Place of Origin: ZheJiang China (Mainland)

Company Profile

HangZhou CHINAMFG has been in power transmission products for 15 years. Our company is an industry transmission solutions manufacuturer and service provider.

The main products are worm reducers, helical worm reducers, helical bevel gear reducers, 90 degree gearbox, spiral bevel reducers, screw jack, standard industrial gearbox etc.

Our speed reducer and industrial gearbox are widely used in different factories, such as chemicals, energy, material handling, environmental, extraction, pulp and paper, steel and metal, food and beverage, and construction industries.

We have strong technical ability, manufacturing according to the ISO9002 quality control system guidelines.

Our industrial Gear, Gearbox, gearmotor and motor are sold to more than 30 countries. High quality, good price, in time response and sincere service are our value and promises. We aim at making happy cooperation with our customers, bring them reliable and comfortable service.

Application

FAQ

1. How to choose a gearbox which meets our requirement?

You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

2. What information shall we give before placing a purchase order?

a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor informationetc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

3. What industries are your gearboxes being used?

Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,

escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc.

| Application: | Machinery |

|---|---|

| Layout: | Helical |

| Hardness: | Hardened Tooth Surface |

| Installation: | as Request |

| Step: | Three-Step |

| Type: | Cylindrical |

| Customization: |

Available

| Customized Request |

|---|

Common Industries and Applications of Miter Gearboxes

Miter gearboxes are widely used across various industries due to their unique capabilities in transmitting motion at a 90-degree angle. Some common industries and applications include: Automotive (steering systems, robotics, machinery, aerospace, construction equipment, marine, medical equipment). The versatility of miter gearboxes to efficiently change the direction of motion and transmit power at right angles makes them valuable components in various industries where precise motion control and compact design are essential.

Proper Installation and Alignment of Miter Gearboxes:

Installing and aligning a miter gearbox correctly is crucial to ensure optimal performance and longevity. Here’s a step-by-step guide on how to do it:

- Preparation: Gather all the necessary tools and equipment for the installation, including mounting hardware, shims, and measuring instruments.

- Positioning: Place the miter gearbox in the desired location, ensuring that it is level and securely supported. Use appropriate mounting brackets or plates to secure the gearbox to the mounting surface.

- Shaft Alignment: Align the input and output shafts of the miter gearbox with the shafts of the connected equipment. Check that the shafts are parallel and collinear for proper alignment.

- Check Tolerance: Measure the axial and radial alignment tolerances between the gearbox and connected equipment. Use precision measuring tools such as dial indicators or laser alignment systems to ensure accurate measurements.

- Adjustment: If alignment tolerances are not within the specified range, make necessary adjustments using shims or other alignment techniques. Gradually add or remove shims as needed to achieve proper alignment.

- Bolt Tightening: Once the miter gearbox is properly aligned, gradually tighten the mounting bolts or fasteners in a crisscross pattern to evenly distribute the load. Use the recommended torque specifications provided by the gearbox manufacturer.

- Lubrication: Apply the recommended lubricant to the gearbox according to the manufacturer’s guidelines. Proper lubrication is essential for minimizing friction and ensuring smooth operation.

- Testing: Before fully operating the system, perform a test run of the miter gearbox to ensure that it operates smoothly and without any abnormal vibrations or noise.

- Final Checks: Double-check the alignment, bolt tightness, and lubrication after the test run. Make any necessary adjustments before putting the system into full operation.

Proper installation and alignment are critical for maximizing the efficiency, reliability, and lifespan of miter gearboxes. Following these steps and consulting the manufacturer’s guidelines will help ensure optimal performance of the gearbox and the entire mechanical system.

Handling High Torque and Speed Requirements with Miter Gearboxes

Miter gearboxes are versatile mechanical components that can be designed to handle both high torque and speed requirements, making them suitable for a wide range of applications.

The ability of miter gearboxes to handle high torque is determined by factors such as the quality of the gear materials, the precision of gear teeth profiles, and the design of the gearbox itself. Miter gearboxes can be engineered with robust and durable materials, optimized gear tooth profiles, and advanced lubrication systems to ensure effective torque transmission without excessive wear or failure.

Similarly, miter gearboxes can be tailored to accommodate high-speed applications. Proper selection of gear materials, lubrication, and design considerations, such as gear tooth geometry and bearing arrangements, contribute to minimizing friction, heat generation, and wear at elevated speeds.

It’s important to note that while miter gearboxes can handle both high torque and speed, there may be practical limitations based on the specific design, size, and intended use of the gearbox. Engineers and designers carefully assess the torque and speed requirements of the application to ensure that the miter gearbox is appropriately designed and configured for optimal performance and longevity.

editor by CX 2023-12-08