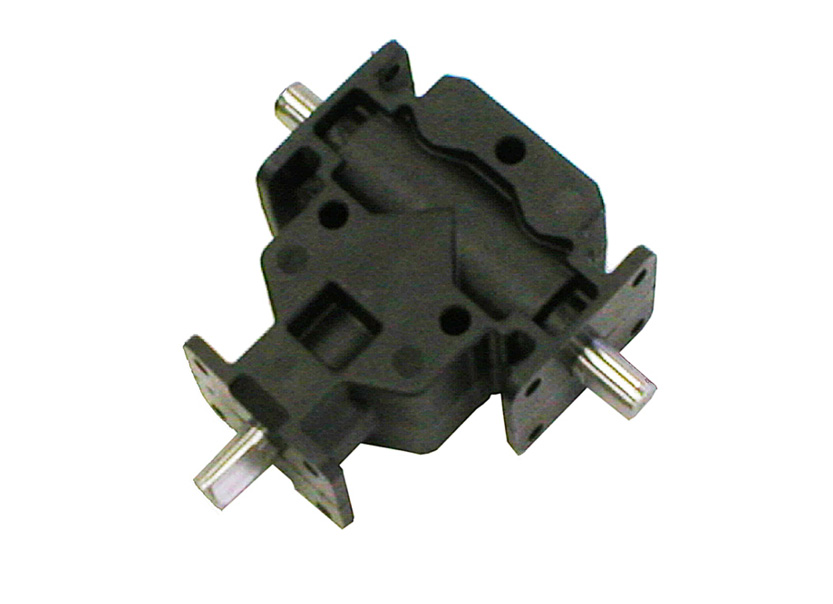

Product Description

Miter Gear Box are available in standard models with a wide range of variations in terms of size, shaft arrangement, speed ratio, and material. Furthermore, with various special specifications, they play important roles in a wide range of applications such as entertainment facilities, chemical plants, food machinery. Such as Hoisting equipment (Motive power is distributed to the right and left sides, and is input to the jack. Driven with 1 motor unit, synchronization is easy and hoisting is possible while keeping a horizontal state.), Multistory parking structure for transporting pallets (Motive power is input from the cross shaft (orthogonal shaft), and the lateral shaft is set as the output shaft. Two units are coupled and synchronized. Driven with 1 motor unit, plural units can be synchronized.), Entertainment facility (Motive power is input from the cross shaft using the lateral dual shaft, and the opposing lateral shaft is rotated in the reverse direction. Using the lateral dual shaft, rotation is possible in different directions with 1 motor unit.), Paper folding machine (Motive power is input to the cross shaft using a ceiling mounted construction, then motive power is distributed to the pulleys of another cross shaft and lateral shaft, and they are driven at the same time), Scraper in water (The screw in the water is driven by motive power from the unit on the ground. It is possible to use the gear box in water. Harmonization with the environment can be promoted with water lubrication.), Iron- and steel-making machine (Motive power is distributed to the right and left sides, as well as to plural shafts, and the line shaft is driven. Synchronized operation can be achieved easily by driving with 1 motor unit. A compact equipment design can be achieved.), Food packaging machine (Packaging quantity is counted by linking the rotary cutter with the counter drive for the number of film sheets. Space savings are possible by linking with the compact Aluminum Gear Box. Besides, when using the Bevel Gear Box, which has excellent corrosion resistance, it is possible to prevent the generation of rust.), Agitator (The agitator is driven by distributing motive power to the right and left sides. One motor unit can drive 2 shafts. Using the Aluminum Gear Box, which has excellent corrosion resistance, it is possible to prevent the generation of rust.)

How Does A Compact Bevel Gearbox Work?

Compact Cubic Gearboxes Videos For Customers Orders

* Malaysia customers bevel 90 degree gearbox 1:1 ratio at 36567X3, registered Capital 500000CNY) is a leading manufacturer and supplier of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Electric Linear Actuators, Gearmotors and Speed Reducers, and Others Linear Motion and Power Transmission Products in China. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CHINAMFG Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications.

Website (English): screw-jacks

Website (English): screw-jacks

Website (Chinese): screw-jacks

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Bottle Capping, Food Processing Equipment |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Right Angle Drive |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type and Vertical Type |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Role of Miter Gearboxes in the Automotive Manufacturing Process

Miter gearboxes play a significant role in the automotive manufacturing process, contributing to various aspects of vehicle production. One of their primary functions is in the assembly and adjustment of automotive components that require precise angle changes.

Automotive manufacturing involves the production of parts and assemblies with specific angles and orientations. Miter gearboxes are used in assembly line machinery to accurately position components such as axles, suspension systems, steering columns, and drivetrain elements. By allowing controlled and precise angular adjustments, miter gearboxes ensure that these components are aligned correctly and securely fitted together.

Furthermore, miter gearboxes find application in robotic systems used for tasks like welding, painting, and material handling in automotive manufacturing. They enable robots to manipulate tools and parts at precise angles, contributing to the accuracy and quality of manufacturing processes.

In summary, miter gearboxes contribute to the efficiency, accuracy, and quality of various processes within the automotive manufacturing industry, helping to produce vehicles that meet stringent quality standards and performance requirements.

Challenges in Using Miter Gearboxes

Miter gearboxes offer various advantages, but there are certain challenges that can arise when using them in mechanical systems:

- Lubrication: Proper lubrication is crucial for miter gearboxes to function smoothly and minimize wear. Inadequate or incorrect lubrication can lead to increased friction, heat generation, and premature component failure.

- Noise: Miter gearboxes can produce noise during operation, especially at high speeds or under heavy loads. This noise is generated due to the interaction between gear teeth and can be a concern in noise-sensitive environments.

- Backlash: Backlash, which is the slight movement or play between gear teeth, can impact the precision of motion transmission in miter gearboxes. Minimizing backlash is essential for applications requiring accurate positioning.

- Alignment: Improper alignment of miter gearboxes can lead to increased wear, noise, and reduced efficiency. Ensuring precise alignment during installation is critical to achieving optimal performance.

- Maintenance: Miter gearboxes require regular maintenance, including lubrication replenishment, to ensure their longevity and performance. Neglecting maintenance can lead to accelerated wear and potential breakdowns.

- Heat Dissipation: Miter gearboxes operating at high speeds or handling heavy loads can generate heat due to friction. Adequate heat dissipation mechanisms, such as cooling fins or fans, may be required to prevent overheating.

Addressing these challenges through proper design, lubrication, alignment, and maintenance practices can help mitigate their impact and ensure the reliable and efficient operation of miter gearboxes in various applications.

Significance of Angle Between Bevel Gears in a Miter Gearbox

The angle between bevel gears in a miter gearbox is of crucial significance as it determines the direction and type of motion transfer between intersecting shafts. In a miter gearbox, the angle between the bevel gears is typically set at 90 degrees.

This 90-degree angle allows the bevel gears to change the direction of rotational motion by redirecting it along a perpendicular axis. This is particularly useful in applications where space constraints or specific layout requirements demand a right-angle change in motion.

The angle also influences the tooth engagement and meshing characteristics of the bevel gears. Proper alignment and precise calculation of this angle are essential to ensure smooth and efficient motion transmission, minimize backlash, and prevent premature wear on the gear teeth.

The choice of angle between the bevel gears is a fundamental design consideration that directly impacts the functionality, performance, and durability of the miter gearbox in various mechanical systems.

editor by CX 2024-01-05