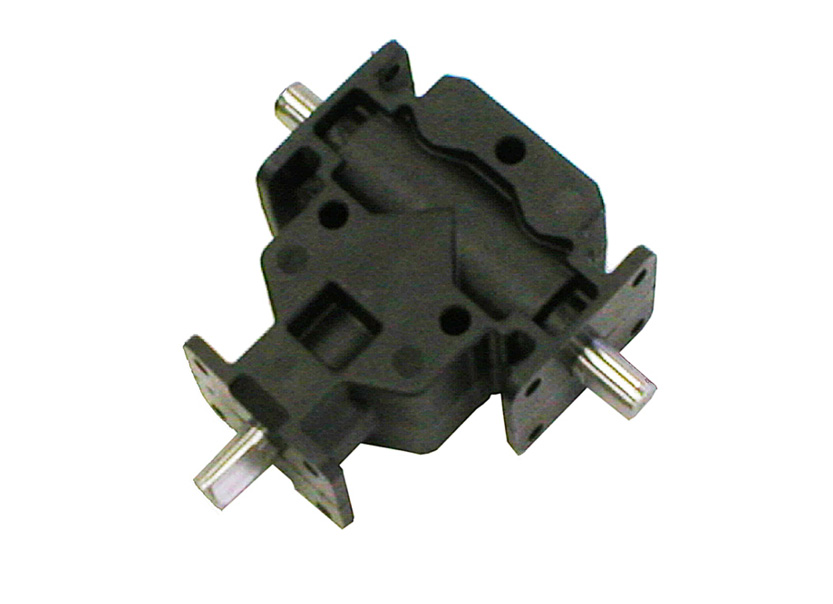

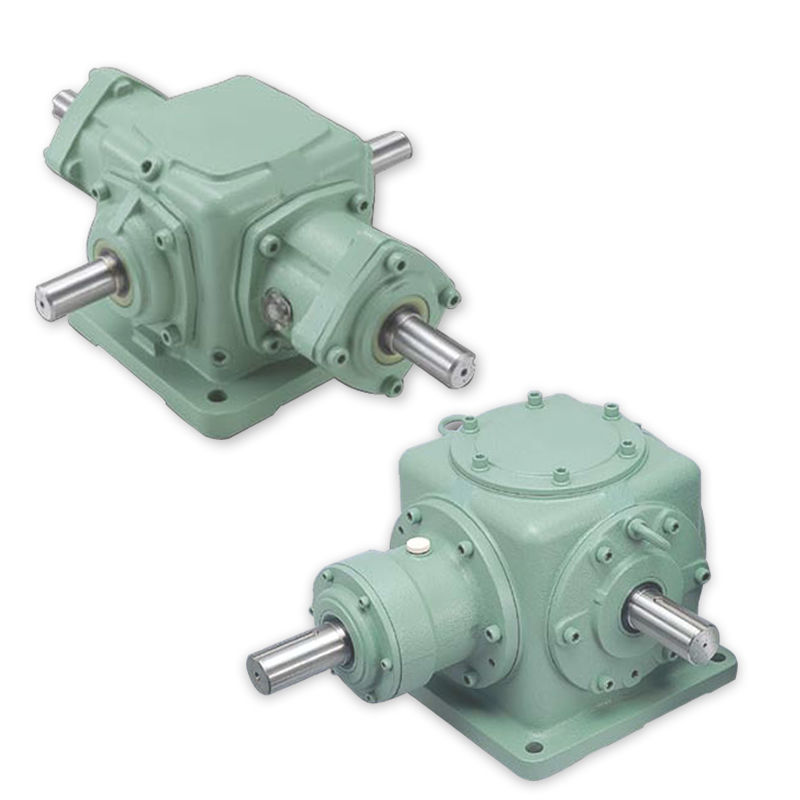

Product Description

Two-way and three-way 90-degree bevel gearboxes transmit power with quiet, dependable spiral bevel gears. These miter speed reducers feature hardened spiral bevel gears and non-magnetic stainless-steel shafts. Another beneficial quality of our 90-degree gearmotors is that they are compact and feature multiple mounting options. The fully enclosed design provides maintenance-free operation while ensuring that internal gears can’t get out of alignment, jam up or become contaminated by debris. Spiral bevel gears have curved teeth to improve contact and reduce the amount of vibration and noise generated when the gear moves at high speeds. The flexibility and enhanced traction of this design also makes spiral bevel gearboxes an excellent option for high-volume applications and those involving steep or varying planes.

How Does A Compact Bevel Gearbox Work?

Compact Cubic Gearboxes Videos For Customers Orders

* Malaysia customers bevel 90 degree gearbox 1:1 ratio at 36567X3, registered Capital 500000CNY) is a leading manufacturer and supplier of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Electric Linear Actuators, Gearmotors and Speed Reducers, and Others Linear Motion and Power Transmission Products in China. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CHINAMFG Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications.

Website (English): screw-jacks

Website (English): screw-jacks

Website (Chinese): screw-jacks

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Bottle Capping, Food Processing Equipment |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Right Angle Drive |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type and Vertical Type |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Role of Miter Gearboxes in the Automotive Manufacturing Process

Miter gearboxes play a significant role in the automotive manufacturing process, contributing to various aspects of vehicle production. One of their primary functions is in the assembly and adjustment of automotive components that require precise angle changes.

Automotive manufacturing involves the production of parts and assemblies with specific angles and orientations. Miter gearboxes are used in assembly line machinery to accurately position components such as axles, suspension systems, steering columns, and drivetrain elements. By allowing controlled and precise angular adjustments, miter gearboxes ensure that these components are aligned correctly and securely fitted together.

Furthermore, miter gearboxes find application in robotic systems used for tasks like welding, painting, and material handling in automotive manufacturing. They enable robots to manipulate tools and parts at precise angles, contributing to the accuracy and quality of manufacturing processes.

In summary, miter gearboxes contribute to the efficiency, accuracy, and quality of various processes within the automotive manufacturing industry, helping to produce vehicles that meet stringent quality standards and performance requirements.

Key Benefits of Using Miter Gearboxes in Angular Transmission Applications

Miter gearboxes offer several key benefits when used in applications requiring angular transmission:

- Precise Angle Transmission: Miter gearboxes excel at transmitting rotational motion at specific angles, ensuring accurate and controlled angular adjustments.

- Compact Design: Their compact and space-saving design allows for efficient integration into machinery and equipment with limited space.

- High Efficiency: Miter gearboxes are engineered for efficient power transmission, minimizing energy losses during angular motion transfer.

- Smooth Operation: The meshing of bevel gears in miter gearboxes results in smooth and stable motion, reducing vibration and noise.

- Wide Range of Angles: Miter gearboxes can handle a broad range of angle requirements, making them versatile for various applications.

- Enhanced Precision: These gearboxes enable precise positioning and alignment of components, crucial in industries like automotive manufacturing.

- Robust and Durable: Constructed from high-quality materials, miter gearboxes offer durability and can withstand demanding operational conditions.

- Customizability: Miter gearboxes can be designed and customized to meet specific angle transmission needs in different industries.

Overall, miter gearboxes are a valuable solution for applications that require accurate and reliable angular transmission, contributing to improved performance and quality in various industries.

Types of Miter Gearboxes and Their Differences

There are two main types of miter gearboxes: straight miter gearboxes and spiral miter gearboxes.

Straight Miter Gearboxes: In straight miter gearboxes, the bevel gears have teeth that are cut straight across the gear’s face. This design allows for efficient power transmission and is suitable for applications where precise motion redirection is required. However, straight miter gearboxes may produce more noise and vibration due to the nature of the gear tooth engagement.

Spiral Miter Gearboxes: Spiral miter gearboxes use bevel gears with spiral-cut teeth. The spiral angle of the teeth helps to reduce noise and vibration by providing smoother tooth engagement and gradual contact between the gear teeth. This design is especially beneficial for applications where quieter operation and improved durability are desired.

The choice between straight and spiral miter gearboxes depends on the specific requirements of the application, including the desired level of noise, vibration, and efficiency. Both types of miter gearboxes offer the same fundamental motion transmission principle, but the design differences impact their performance characteristics.

editor by CX 2023-10-17