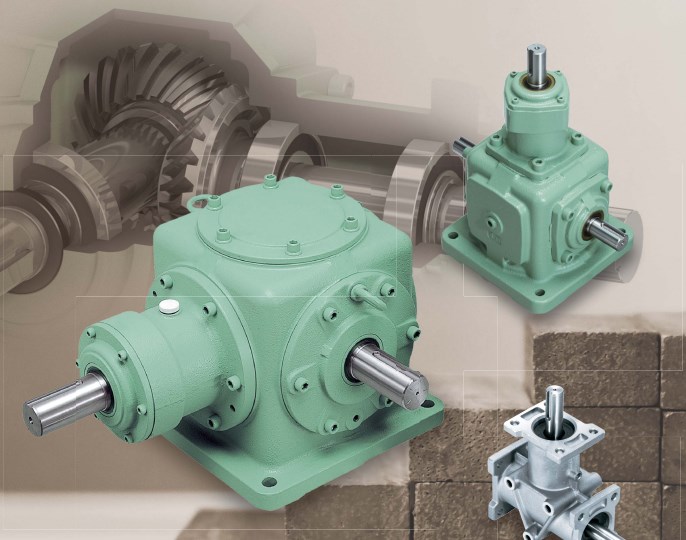

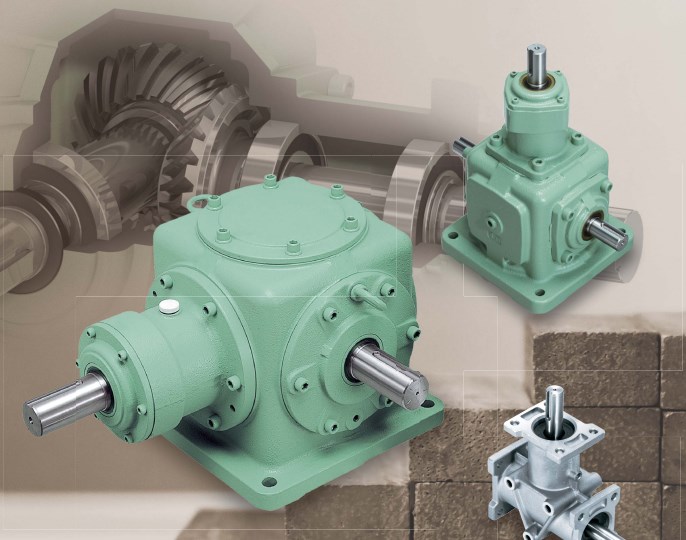

Product Description

We offer a complete range of right-angle spiral bevel gearboxes, which include a wide range of standard ratios and shaft options, for applications requiring high precision and space-saving installation. A spiral bevel gear is a bevel gear with helical teeth. A spiral bevel gear set should always be replaced in pairs i.e. both the left hand and right hand gears should be replaced together since the gears are manufactured and lapped in pairs. High transmission efficiency, Stable transmission ratio, Large arc overlap coefficient, High load capacity, Smooth transmission, Reliable operation, Long lifetime, Low noise.

How Does A Compact Bevel Gearbox Work?

Compact Cubic Gearboxes Videos For Customers Orders

* Malaysia customers bevel 90 degree gearbox 1:1 ratio at 36567X3, registered Capital 500000CNY) is a leading manufacturer and supplier of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Electric Linear Actuators, Gearmotors and Speed Reducers, and Others Linear Motion and Power Transmission Products in China. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CHINAMFG Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications.

Website (English): screw-jacks

Website (English): screw-jacks

Website (Chinese): screw-jacks

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Bottle Capping, Food Processing Equipment |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Right Angle Drive |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type and Vertical Type |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Distinguishing Miter Gearboxes from Other Types of Gear Systems

Miter gearboxes possess distinct characteristics that set them apart from other types of gear systems, making them suitable for specific applications:

1. Angular Motion Transmission: Miter gearboxes excel at transmitting motion at a precise angle, typically 90 degrees, between intersecting shafts. This is achieved through the use of bevel gears with matching angles on their teeth.

2. Compact and Space-Saving Design: Miter gearboxes have a compact form factor, making them ideal for applications with limited space. Their right-angle configuration allows them to efficiently change the direction of motion without requiring additional components.

3. High Efficiency: Due to their precision machining and careful design, miter gearboxes offer high efficiency in transmitting power between intersecting shafts. They minimize backlash and friction, resulting in smooth and efficient motion transfer.

4. Wide Range of Applications: Miter gearboxes find use in various industries, including automotive, robotics, machinery, and more. Their ability to redirect motion and transmit power at right angles makes them versatile for different mechanical systems.

5. Backlash Minimization: Miter gearboxes are designed to minimize backlash through precise tooth profile shaping, gear alignment, and high-quality bearings. This ensures accurate and reliable motion without unwanted play.

6. Specialized Applications: While other gear systems like helical or spur gears offer advantages in certain scenarios, miter gearboxes excel in applications requiring angular transmission, compactness, and efficient power transfer at right angles.

Overall, miter gearboxes stand out for their unique ability to transmit motion at a specific angle and their compact, efficient, and versatile design, making them a valuable choice for a range of mechanical applications.

Efficient Power Transmission and Torque Transfer with Miter Gearboxes

Miter gearboxes play a crucial role in ensuring efficient power transmission and torque transfer in mechanical systems. Here’s how they contribute:

- Optimal Gear Meshing: Miter gearboxes are designed with precision-cut bevel gears that mesh seamlessly, minimizing energy losses and ensuring a high degree of power transfer efficiency.

- Angular Transmission: These gearboxes excel at transmitting rotational motion at specific angles, allowing torque to be efficiently redirected or transferred between intersecting shafts.

- Multiple Gear Meshes: Miter gearboxes often have multiple gear meshes, distributing torque and load evenly across the gears, reducing wear and enhancing overall efficiency.

- Compact and Sturdy Design: The compact construction of miter gearboxes reduces the distance between shafts, minimizing flex and misalignment that could lead to power losses.

- High-Quality Materials: Miter gearboxes are constructed from durable materials that can withstand high torque and load, ensuring reliable power transmission over extended periods.

- Smooth Motion Transfer: The bevel gears in miter gearboxes facilitate smooth and uniform motion transfer, reducing vibration and minimizing energy dissipation.

- Minimal Backlash: Properly designed miter gearboxes have minimal backlash, ensuring that torque is efficiently transmitted without significant play or lost motion.

Overall, miter gearboxes optimize power transmission and torque transfer, making them suitable for applications that demand efficient and reliable angular motion conversion and redirection.

Function of Bevel Gears in a Miter Gearbox

Bevel gears in a miter gearbox are responsible for changing the direction of rotational motion between intersecting shafts. They achieve this by utilizing the principle of conical gear teeth. The bevel gears have tapered tooth profiles that allow them to mesh together at a specific angle, typically 90 degrees in the case of a miter gearbox.

When one bevel gear (the driving gear) rotates, its conical teeth engage with the teeth of the other bevel gear (the driven gear) at the desired angle. As a result, the rotational motion is transmitted from the driving gear to the driven gear, causing the output shaft to rotate perpendicular to the input shaft. This change in direction allows the miter gearbox to redirect motion along a different axis, making it suitable for applications where a 90-degree turn is required.

The precise tooth geometry and alignment of the bevel gears ensure smooth and efficient motion transfer, enabling the miter gearbox to effectively transmit torque and power while changing the direction of rotation.

editor by CX 2024-04-04