Product Description

EWS series adopts helical gear – worm gear speed reducer motor integrated drive to improve the torque and efficiency of the speed reducer with wide range of rotating speed and good universality, it is applicable to varied installation modes and features safe and reliable performance, and long service life, additionally, it also complies with the international standard.

Characteristic advantage

1.Combination of helical gear and worm, vertical output, compact structure, high speed ratio.

2.The concave-convex surface of the product provides the function of heat dissipation, and features strong vibration absorption, low temperature rise, low noise.

3.The product features high drive precision, and is especially suitable for the site with frequent start, is can be connected with varied speed reducers and configuring varied motor drives, and can be installed at the 90º drive operation site.

Specification parameter

Installation type : Foot,flange,small flange,torque arm.

Output type : Solid shaft,hollow shaft,hollow shaft with shrink disk,spline hollow shaft.

Input type : Motor,input shaft and flange

technical parameters : ratio i=23.8~389,combination of EWS/EWR is up to26688

Efficiency : ratio i=23.8~389,77%;ratio i=73.7~389,62%;and combination of EWS/EWR57%.

Industrial Application

Power Plant Equipment

Metallurgical Industry

Metal Forming Machinery

Petrochemical Industry

Mining Machine

Hoisting Machinery

Construction Industry

Environmental Protection Industry

Cable Industry

Food Machinery

Certificates

Passed ” ISO 9001 International Quality System Certificate”,”Europe CE Certificate”, ” Swiss SGS Certificate”,”High-tech enterprise certificate of ZheJiang city”,”Excellent performance management enterprise of ZheJiang city”,etc.

FAQ

1. Q: Can you make as per custom drawing?

A: Yes, we offer customized service for customers.

2. Q: Are you a factory or trading company?

A. We are manufacturer in ZheJiang China.

3. Q: What’s your MOQ?

A: One piece.

4. Q: What’s your production time?

A: 7-15 working days after receiving payment.

5. Q: What’s your payment terms?

A: T/T, 30% payment in advance, 70% balance payment should be paid before shipping.

6. Q: What’s your package?

A: In wooden box packaging.

ZheJiang CHINAMFG Gear Reducer Co.,Ltd., former a joint venture invested by is a ZheJiang CHINAMFG GROUP and Well Company of America.We are professional manufacturer of the gear reducers and specialize in the gear reducers area in China for 20 years. CHINAMFG has excellent R&D team,top-ranking production and test equipment.So we have the strong power in the developing and manufacturing the standards type as well as the customized type gear reducer for our customers. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Gear Shape: | Helical Worm Gear |

| Step: | Three-Step |

| Type: | Worm Reducer |

| Customization: |

Available

| Customized Request |

|---|

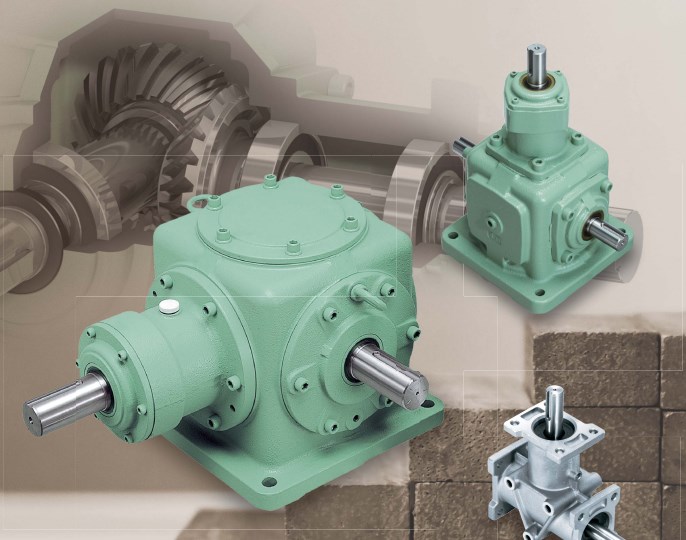

Performance of Miter Gearboxes in Applications Requiring Precise Angle Changes

Miter gearboxes excel in applications that demand precise angle changes in motion transmission. Their ability to efficiently and accurately redirect rotational motion by 90 degrees makes them ideal for tasks where precise angular positioning is essential. Industries such as robotics, automation, machinery, and manufacturing often utilize miter gearboxes to achieve accurate and repeatable angular changes, ensuring proper alignment and movement of components. The compact and space-saving design of miter gearboxes further enhances their suitability for applications that require tight spatial constraints and precise motion control.

Efficient Power Transmission and Torque Transfer with Miter Gearboxes

Miter gearboxes play a crucial role in ensuring efficient power transmission and torque transfer in mechanical systems. Here’s how they contribute:

- Optimal Gear Meshing: Miter gearboxes are designed with precision-cut bevel gears that mesh seamlessly, minimizing energy losses and ensuring a high degree of power transfer efficiency.

- Angular Transmission: These gearboxes excel at transmitting rotational motion at specific angles, allowing torque to be efficiently redirected or transferred between intersecting shafts.

- Multiple Gear Meshes: Miter gearboxes often have multiple gear meshes, distributing torque and load evenly across the gears, reducing wear and enhancing overall efficiency.

- Compact and Sturdy Design: The compact construction of miter gearboxes reduces the distance between shafts, minimizing flex and misalignment that could lead to power losses.

- High-Quality Materials: Miter gearboxes are constructed from durable materials that can withstand high torque and load, ensuring reliable power transmission over extended periods.

- Smooth Motion Transfer: The bevel gears in miter gearboxes facilitate smooth and uniform motion transfer, reducing vibration and minimizing energy dissipation.

- Minimal Backlash: Properly designed miter gearboxes have minimal backlash, ensuring that torque is efficiently transmitted without significant play or lost motion.

Overall, miter gearboxes optimize power transmission and torque transfer, making them suitable for applications that demand efficient and reliable angular motion conversion and redirection.

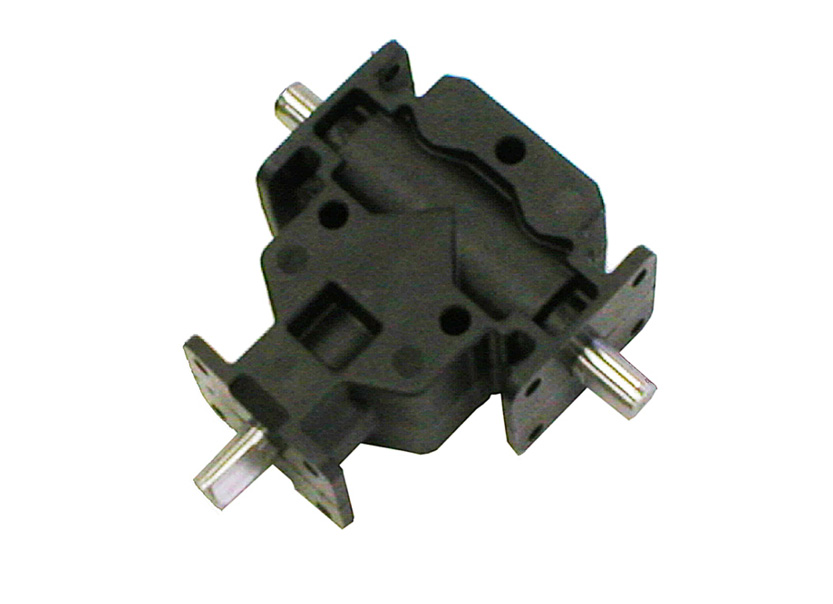

Handling High Torque and Speed Requirements with Miter Gearboxes

Miter gearboxes are versatile mechanical components that can be designed to handle both high torque and speed requirements, making them suitable for a wide range of applications.

The ability of miter gearboxes to handle high torque is determined by factors such as the quality of the gear materials, the precision of gear teeth profiles, and the design of the gearbox itself. Miter gearboxes can be engineered with robust and durable materials, optimized gear tooth profiles, and advanced lubrication systems to ensure effective torque transmission without excessive wear or failure.

Similarly, miter gearboxes can be tailored to accommodate high-speed applications. Proper selection of gear materials, lubrication, and design considerations, such as gear tooth geometry and bearing arrangements, contribute to minimizing friction, heat generation, and wear at elevated speeds.

It’s important to note that while miter gearboxes can handle both high torque and speed, there may be practical limitations based on the specific design, size, and intended use of the gearbox. Engineers and designers carefully assess the torque and speed requirements of the application to ensure that the miter gearbox is appropriately designed and configured for optimal performance and longevity.

editor by CX 2024-03-28