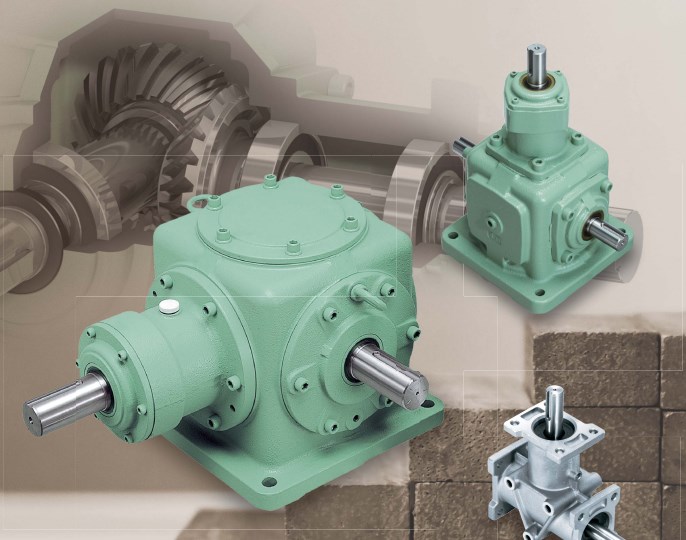

Product Description

The Stainless-steel gearboxes are intended for the use in the food industry. They are based on our proven standard gearboxes from the range of single-stage bevel gearboxes and have therefore the same external dimensions. All outside parts are made of high-quality stainless steel. The shaft seal rings installed in the type have an additional dust lip. The housing and the flanges do not contain any bores or other dust pockets. Required mounting bores will be drilled application-specifically according to your specifications. Housing, flanges and shafts are made of rust-proof stainless steel. Hygiene-design bevel gearboxes: The material selection, the design, and the surface finish ensure optimum cleaning properties and maximum hygiene. The stainless-steel design of all external components efficiently prevents any form of corrosion and is additionally acid-proof and alkaline-resistant. The typical product qualities such as high running smoothness, high efficiency, robustness, running accuracy are guaranteed, and an excellent ability to supply goes without saying. Hygienic-design gearboxes are our response to the requirements of the pharmaceutical and food-processing industries.

How Does A Corrosion-resistant Bevel Gearbox Work?

Compact Stainless Steel Bevel Gearboxes Videos For Customers Orders

* Germany Customer Stainless Steel Spiral Bevel Gearbox/Stainless Steel Bevel Gear Drives Video:

* 16567X3, registered Capital 500000CNY) is a leading manufacturer and supplier of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Electric Linear Actuators, Gearmotors and Speed Reducers, and Others Linear Motion and Power Transmission Products in China. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CHINAMFG Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications.

Website (English): screw-jacks

Website (English): screw-jacks

Website (Chinese): screw-jacks

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car, Food Industry Machinery, Glass Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase, Transmission |

| Layout: | Right Angle Drive |

| Hardness: | Hardened Tooth Surface |

| Installation: | Universal Mounting |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Distinguishing Miter Gearboxes from Other Types of Gear Systems

Miter gearboxes possess distinct characteristics that set them apart from other types of gear systems, making them suitable for specific applications:

1. Angular Motion Transmission: Miter gearboxes excel at transmitting motion at a precise angle, typically 90 degrees, between intersecting shafts. This is achieved through the use of bevel gears with matching angles on their teeth.

2. Compact and Space-Saving Design: Miter gearboxes have a compact form factor, making them ideal for applications with limited space. Their right-angle configuration allows them to efficiently change the direction of motion without requiring additional components.

3. High Efficiency: Due to their precision machining and careful design, miter gearboxes offer high efficiency in transmitting power between intersecting shafts. They minimize backlash and friction, resulting in smooth and efficient motion transfer.

4. Wide Range of Applications: Miter gearboxes find use in various industries, including automotive, robotics, machinery, and more. Their ability to redirect motion and transmit power at right angles makes them versatile for different mechanical systems.

5. Backlash Minimization: Miter gearboxes are designed to minimize backlash through precise tooth profile shaping, gear alignment, and high-quality bearings. This ensures accurate and reliable motion without unwanted play.

6. Specialized Applications: While other gear systems like helical or spur gears offer advantages in certain scenarios, miter gearboxes excel in applications requiring angular transmission, compactness, and efficient power transfer at right angles.

Overall, miter gearboxes stand out for their unique ability to transmit motion at a specific angle and their compact, efficient, and versatile design, making them a valuable choice for a range of mechanical applications.

Challenges in Using Miter Gearboxes

Miter gearboxes offer various advantages, but there are certain challenges that can arise when using them in mechanical systems:

- Lubrication: Proper lubrication is crucial for miter gearboxes to function smoothly and minimize wear. Inadequate or incorrect lubrication can lead to increased friction, heat generation, and premature component failure.

- Noise: Miter gearboxes can produce noise during operation, especially at high speeds or under heavy loads. This noise is generated due to the interaction between gear teeth and can be a concern in noise-sensitive environments.

- Backlash: Backlash, which is the slight movement or play between gear teeth, can impact the precision of motion transmission in miter gearboxes. Minimizing backlash is essential for applications requiring accurate positioning.

- Alignment: Improper alignment of miter gearboxes can lead to increased wear, noise, and reduced efficiency. Ensuring precise alignment during installation is critical to achieving optimal performance.

- Maintenance: Miter gearboxes require regular maintenance, including lubrication replenishment, to ensure their longevity and performance. Neglecting maintenance can lead to accelerated wear and potential breakdowns.

- Heat Dissipation: Miter gearboxes operating at high speeds or handling heavy loads can generate heat due to friction. Adequate heat dissipation mechanisms, such as cooling fins or fans, may be required to prevent overheating.

Addressing these challenges through proper design, lubrication, alignment, and maintenance practices can help mitigate their impact and ensure the reliable and efficient operation of miter gearboxes in various applications.

Types of Miter Gearboxes and Their Differences

There are two main types of miter gearboxes: straight miter gearboxes and spiral miter gearboxes.

Straight Miter Gearboxes: In straight miter gearboxes, the bevel gears have teeth that are cut straight across the gear’s face. This design allows for efficient power transmission and is suitable for applications where precise motion redirection is required. However, straight miter gearboxes may produce more noise and vibration due to the nature of the gear tooth engagement.

Spiral Miter Gearboxes: Spiral miter gearboxes use bevel gears with spiral-cut teeth. The spiral angle of the teeth helps to reduce noise and vibration by providing smoother tooth engagement and gradual contact between the gear teeth. This design is especially beneficial for applications where quieter operation and improved durability are desired.

The choice between straight and spiral miter gearboxes depends on the specific requirements of the application, including the desired level of noise, vibration, and efficiency. Both types of miter gearboxes offer the same fundamental motion transmission principle, but the design differences impact their performance characteristics.

editor by CX 2024-03-29