Product Description

We are professional best hollow shaft rights angle gear drive, bevel gears 2:1, right angle gearbox 1:1 15hp manufacturers and suppliers from China. All hollow shaft rights angle gear drive, bevel gears 2:1, right angle gearbox 1:1 15hp will be tested and inspection reports before products shipment.

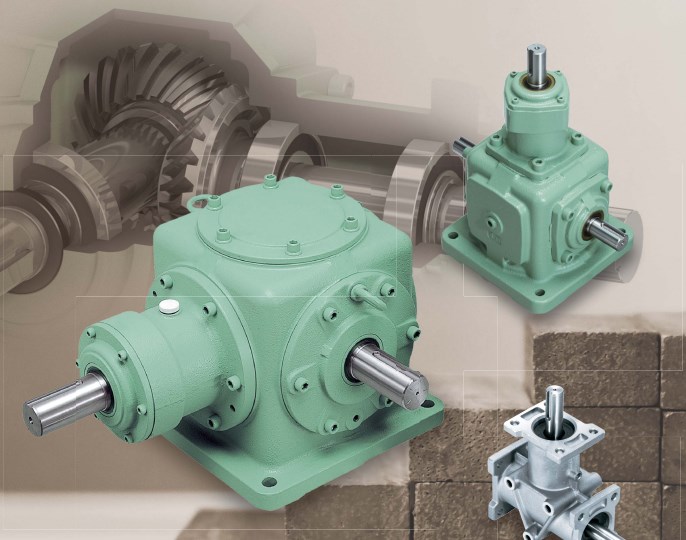

JTP Series Cubic Bevel Gearbox

Jacton JTP series cubic bevel gearbox is also known as cubic right angle miter gearbox, cubic 90 degree bevel gearbox, cubic miter bevel gear box, or cubic spiral bevel gear reducers. JTP series cubic bevel gearbox is a right-angle shaft type gear box of spiral bevel gears for general applications with high transmission capacity, high performance and high efficiency. 1:1, 1.5:1, 2:1, 3:1, 4:1 and 5:1 gear ratios as standard. 2 way(one input 1 output), 3 way(one input 2 output, or 2 input 1 output), 4 way(two input 2 output) drive shafts as standard. CHINAMFG shaft as standard, customize hollow shaft or motor flange to bolt an IEC motor flange. Maximum torque 1299N.m. Maximum input and output speed 1450RPM. There are 8 models: JTP65 mini cubic bevel gearbox, JTP90 cubic bevel gearbox, JTP110 cubic bevel gearbox, JTP140 cubic bevel gearbox, JTP170 cubic bevel gearbox, JTP210 cubic bevel gearbox, JTP240 cubic bevel gearbox and JTP280 cubic bevel gearbox.

| JTP65 Mini Cubic Bevel Gearbox 1. bevel gear ratio 1:1 2. CHINAMFG drive shafts diameter12mm 3. CHINAMFG input and output shaft shafts 4. 2 way, 3 way, 4 way gearbox 5. input power maximum 1.8Kw 6. drive torque maximum 13.5Nm 7. maximum input 156567X3, registered Capital 500000CNY) is a leading manufacturer and supplier in China for screw jacks (mechanical actuators), bevel gearboxes, lifting systems, linear actuators, gearmotors and speed reducers, and others linear motion and power transmission products. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CHINAMFG Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications. Website 1: http://screw-jacks Website 2:

Role of Miter Gearboxes in the Automotive Manufacturing ProcessMiter gearboxes play a significant role in the automotive manufacturing process, contributing to various aspects of vehicle production. One of their primary functions is in the assembly and adjustment of automotive components that require precise angle changes. Automotive manufacturing involves the production of parts and assemblies with specific angles and orientations. Miter gearboxes are used in assembly line machinery to accurately position components such as axles, suspension systems, steering columns, and drivetrain elements. By allowing controlled and precise angular adjustments, miter gearboxes ensure that these components are aligned correctly and securely fitted together. Furthermore, miter gearboxes find application in robotic systems used for tasks like welding, painting, and material handling in automotive manufacturing. They enable robots to manipulate tools and parts at precise angles, contributing to the accuracy and quality of manufacturing processes. In summary, miter gearboxes contribute to the efficiency, accuracy, and quality of various processes within the automotive manufacturing industry, helping to produce vehicles that meet stringent quality standards and performance requirements.

Challenges in Using Miter GearboxesMiter gearboxes offer various advantages, but there are certain challenges that can arise when using them in mechanical systems:

Addressing these challenges through proper design, lubrication, alignment, and maintenance practices can help mitigate their impact and ensure the reliable and efficient operation of miter gearboxes in various applications.

Transmission of Motion in Miter GearboxesMiter gearboxes transmit motion at an angle between intersecting shafts through the use of bevel gears with perpendicular axes. These bevel gears have teeth that are cut at a 45-degree angle to the gear’s face and mesh with each other. When one bevel gear is rotated, its teeth engage with the teeth of the other bevel gear, resulting in torque transfer and motion redirection at a 90-degree angle. As the input shaft turns the first bevel gear, its teeth push against the teeth of the second bevel gear. This interaction causes the second bevel gear to rotate around its perpendicular axis, transferring motion to the output shaft. The gear ratio and the number of teeth on each gear determine the speed and torque characteristics of the transmitted motion. Due to their ability to redirect motion while maintaining efficient power transmission, miter gearboxes are commonly used in applications where a change in direction is necessary, such as in steering systems, printing machinery, and other mechanical systems requiring precise angular alignment.

Tags: 1 gearbox price | angle gearbox | angle shaft | best gear | bevel gear | bevel gear oem | bevel gear price | bevel gearbox | bevel gearbox right angle | china gearbox | china gears | differential gear | differential gears | differential shaft | gear | gear best | gear bevel | gear bevel gear | gear gearbox | gear gears | gear shaft | gearbox | gearbox 1: 1 | gearbox china | gearbox differential | gearbox gear | gearbox price | gearbox shaft | gears | gears gears gears | hollow gearbox | hollow shaft | hollow shaft gearbox | oem gear | oem gearbox | oem shaft | right angle bevel gearbox | right angle gearbox | shaft | shaft 1 | shaft gear | shaft price

|