Product Description

Low Backlash Worm Gearbox Efficiency Servo Gear Boxes reducer zero electric transmission motor China Manufacturers for Energy Aerospace Industrial Gearboxes

The low backlash drive units HPCNHS type are available in 4 sizes. Each size includes 2 ratios which are 30:1 and 60:1.

The drive units HPCNHS are built with a minimum backlash which can be adjusted due to the duplex toothing of the gears.

The low backlash drive units are built for medium power transmission.

Worm Gear Units:

The NHS-Range gearboxes is available in 4 model sizes and 2 standard ratios.The gearbox size is identical to the centreline distance.

Low backlash Features :

— Worm gear gyration backlash can be adjusted to less than 1 arc.

— Reducer can be re-adjusted the gap after using .

— Input with coupling : reliable without backlash .

— Output using conical clamping ring couplings : reliable without backlash.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Role of Miter Gearboxes in the Automotive Manufacturing Process

Miter gearboxes play a significant role in the automotive manufacturing process, contributing to various aspects of vehicle production. One of their primary functions is in the assembly and adjustment of automotive components that require precise angle changes.

Automotive manufacturing involves the production of parts and assemblies with specific angles and orientations. Miter gearboxes are used in assembly line machinery to accurately position components such as axles, suspension systems, steering columns, and drivetrain elements. By allowing controlled and precise angular adjustments, miter gearboxes ensure that these components are aligned correctly and securely fitted together.

Furthermore, miter gearboxes find application in robotic systems used for tasks like welding, painting, and material handling in automotive manufacturing. They enable robots to manipulate tools and parts at precise angles, contributing to the accuracy and quality of manufacturing processes.

In summary, miter gearboxes contribute to the efficiency, accuracy, and quality of various processes within the automotive manufacturing industry, helping to produce vehicles that meet stringent quality standards and performance requirements.

Challenges in Using Miter Gearboxes

Miter gearboxes offer various advantages, but there are certain challenges that can arise when using them in mechanical systems:

- Lubrication: Proper lubrication is crucial for miter gearboxes to function smoothly and minimize wear. Inadequate or incorrect lubrication can lead to increased friction, heat generation, and premature component failure.

- Noise: Miter gearboxes can produce noise during operation, especially at high speeds or under heavy loads. This noise is generated due to the interaction between gear teeth and can be a concern in noise-sensitive environments.

- Backlash: Backlash, which is the slight movement or play between gear teeth, can impact the precision of motion transmission in miter gearboxes. Minimizing backlash is essential for applications requiring accurate positioning.

- Alignment: Improper alignment of miter gearboxes can lead to increased wear, noise, and reduced efficiency. Ensuring precise alignment during installation is critical to achieving optimal performance.

- Maintenance: Miter gearboxes require regular maintenance, including lubrication replenishment, to ensure their longevity and performance. Neglecting maintenance can lead to accelerated wear and potential breakdowns.

- Heat Dissipation: Miter gearboxes operating at high speeds or handling heavy loads can generate heat due to friction. Adequate heat dissipation mechanisms, such as cooling fins or fans, may be required to prevent overheating.

Addressing these challenges through proper design, lubrication, alignment, and maintenance practices can help mitigate their impact and ensure the reliable and efficient operation of miter gearboxes in various applications.

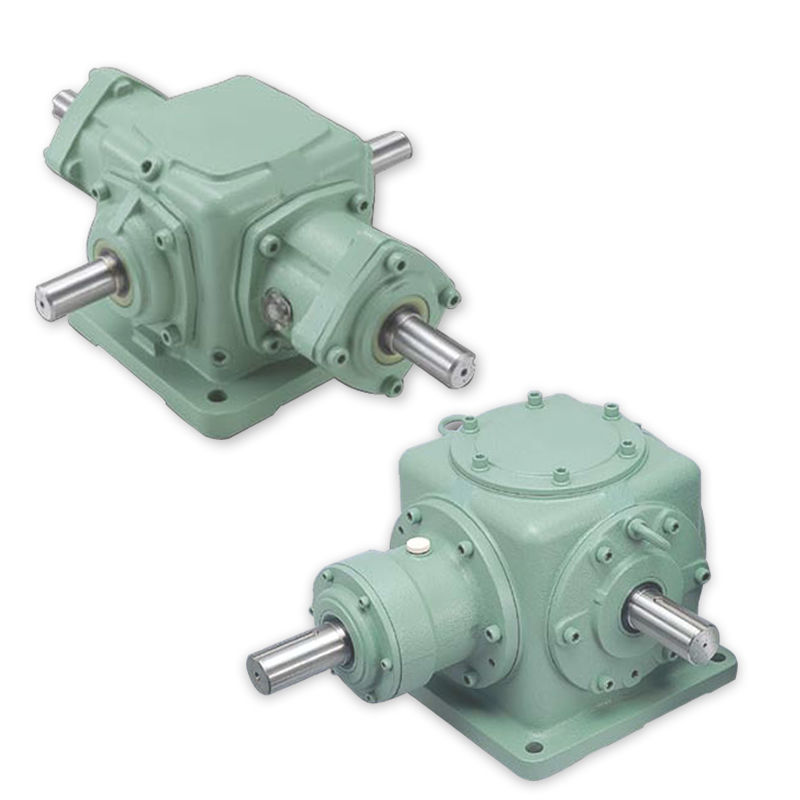

Function of Miter Gearbox in Mechanical Systems

A miter gearbox is a type of gear arrangement that allows rotational motion to be transmitted at a 90-degree angle between intersecting shafts. It consists of two bevel gears with perpendicular axes, which makes it suitable for changing the direction of motion in a mechanical system.

Miter gearboxes function by meshing the teeth of the two bevel gears, which are cut at an angle of 45 degrees. As one gear rotates, its teeth engage with the teeth of the other gear, transmitting torque and motion perpendicular to the input shaft. This 90-degree redirection of motion is crucial for applications where space constraints or specific mechanical configurations require changes in direction.

These gearboxes are commonly used in situations where components need to be rotated or aligned at right angles, such as in automotive steering systems, printing presses, woodworking machinery, and more. The ability to efficiently transfer motion at a 90-degree angle makes miter gearboxes essential in various industrial and mechanical applications.

editor by CX 2024-03-29