Product Description

Product description

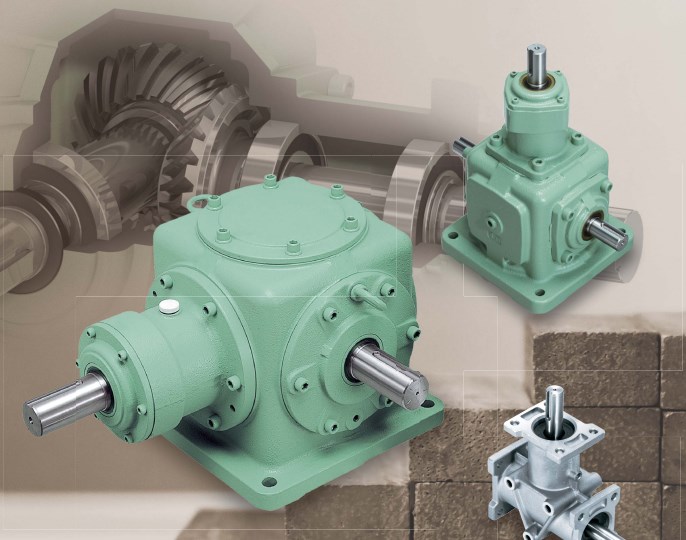

Good Quality Worm Transmission Gearbox Manufacturers For Agricultural Machine

Our Gearbox has many items for your choosing and we can produce as per your drawing or sample to meet your special request

1. Large output torque

2. Safe, reliable, economical and durable

3. Stable transmission, quiet operation

4. High carrying ability

5. High modularization design, may equip with various outer power input conveniently. Same machine type may equip with various power motor. It is easy to realize the combination and junction between every machine type

6. Transmission ratio: Fine division, wide scope. The combined machine type may form very large transmission ratio, i. E. Output very low rotary speed.

7. Form of installation: The position to be installed is not limited.

8. High strength, compact the box body of high strength cast iron, gear and gear shaft adapts the gas carbonization, quenching and fine grinding process, therefore the bearing capacity of unit volume is high.

9. Long life: Under the condition of correct type chosen(including choosing suitable operation parament ) normal operation and maintenance, the life if main parts speed reducer(except wearing parts)should not be less than 2

270

15

3

340

1

380

5

450

300

4-1100

300-800

1000-9000

B

|

Type |

Max. torque(N.m) |

Range of ratios(i) |

Max. Input speed (rpm) |

Braking torque (N.m) |

Design |

|

|

Excavator |

Crane |

|||||

|

CB 700L 1A |

1000 |

1200 |

3.38-7.2 |

2000 |

50-400 |

A |

|

CB 701L 1A |

1800 |

2400 |

3.38-7.2 |

2000 |

50-400 |

A |

|

CB 703L 2A |

2500 |

3500 |

12-44 |

3000 |

50-400 |

A |

|

CB 705L 2A |

5000 |

6500 |

12-44 |

3000 |

50-400 |

A |

|

CB 705L 2B |

5000 |

6500 |

12-44 |

3000 |

50-400 |

B |

|

CB 706L 2B |

7500 |

10000 |

13-44 |

3000 |

400-1000 |

B |

|

CB 707L 2B |

9000 |

15000 |

13-43 |

3000 |

400-1000 |

B |

|

CB 709L 2B |

12000 |

20000 |

14-47 |

3000 |

400-1000 |

B |

|

CB 710L 2B |

18000 |

30000 |

14-45 |

2500 |

400-1000 |

B |

|

CB 711L 2B |

20000 |

35000 |

14-45 |

2000 |

400-1000 |

B |

|

CB 713L 3B |

40000 |

55000 |

50-300 |

2000 |

400-1000 |

B |

|

CB 715L 3B |

70000 |

80000 |

52-320 |

2000 |

400-1000 |

B |

|

Type |

Max. torque(N.m) |

Range of ratios(i) |

Mx. Input speed (rpm) |

Braking torque (N.m) |

||

|

Wheel drives |

Track drives |

Wheel drives |

Track drives |

|||

|

CB 600L 1 |

CB 400L 1 |

800 |

1000 |

4.77 |

1000 |

200-250 |

|

CB 601L 1 |

CB 401L 1 |

1750 |

2200 |

6.2 |

1000 |

250-350 |

|

CB 602L 2 |

CB 602L 2 |

4000 |

5000 |

12.4-25.8 |

3000 |

—— |

|

CB 603L 2 |

CB 403L 2 |

4000 |

4000 |

15.4-40 |

3000 |

220-310 |

|

CB 605L 2 |

CB 405L 2 |

7000 |

10000 |

22-53 |

3000 |

220-310 |

|

CB 606L 2, L3 |

CB 406L 2, L3 |

12000 |

18000 |

30-173 |

3000 |

250-800 |

|

CB 607L 2, L3 |

CB 407L 2, L3 |

17000 |

23000 |

33-122 |

3000 |

300-600 |

|

CB 609L 2, L3 |

CB 409L 2, L3 |

23000 |

30000 |

33-145 |

3000 |

300-600 |

|

CB 610L 2, L3 |

CB 410L 2, L3 |

30000 |

36000 |

20-113 |

2500 |

300-800 |

|

CB 611L 2, L3 |

CB 411L 2, L3 |

36000 |

45000 |

41-173 |

2000 |

300-800 |

|

CB 613L 3 |

CB 413L 3 |

45000 |

60000 |

81-142 |

2000 |

400-800 |

|

CB 615L 3 |

CB 415L 3 |

60000 |

85000 |

108-156 |

2000 |

600-1000 |

Recommend Products

CHINAMFG High Torque Transmission Gearboxes

WPA WPS Cast Iron Case Worm Gearbox

Marine Gearbox For Work Boat

Gearbox Manufacturers For Agricultural Machine

90 Degree Reducer For Concrete Mixer

Worm Gearbox Reduction For Conveyor Mill Machine

Right Angle Worm Gear Box

Gear Reducers For Belt Conveyor

Speed Worm Gear Reducer

HangZhou CHINAMFG Industry Co., Ltd. is a specialized supplier of a full range of chains, sprockets, gears, gear racks, v belt pulley, timing pulley, V-belts, couplings, machined parts and so on.

Due to our CHINAMFG in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements, we have obtained the trust of buyers worldwide. Having accumulated precious experience in cooperating with foreign customers, our products are selling well in the American, European, South American and Asian markets. Our products are manufactured by modern computerized machinery and equipment. Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.

Additionally, all our production procedures are in compliance with ISO9001 standards. We also can design and make non-standard products to meet customers’ special requirements. Quality and credit are the bases that make a corporation alive. We will provide best services and high quality products with all sincerity. If you need any information or samples, please contact us and you will have our soon reply.

FAQ:

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 10 workdays.

2.Production Lead-times: 20-40 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we’ll check.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Electric Drill Speed Reducer |

|---|---|

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops |

| Output Speed: | 60rpm |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Distinguishing Miter Gearboxes from Other Types of Gear Systems

Miter gearboxes possess distinct characteristics that set them apart from other types of gear systems, making them suitable for specific applications:

1. Angular Motion Transmission: Miter gearboxes excel at transmitting motion at a precise angle, typically 90 degrees, between intersecting shafts. This is achieved through the use of bevel gears with matching angles on their teeth.

2. Compact and Space-Saving Design: Miter gearboxes have a compact form factor, making them ideal for applications with limited space. Their right-angle configuration allows them to efficiently change the direction of motion without requiring additional components.

3. High Efficiency: Due to their precision machining and careful design, miter gearboxes offer high efficiency in transmitting power between intersecting shafts. They minimize backlash and friction, resulting in smooth and efficient motion transfer.

4. Wide Range of Applications: Miter gearboxes find use in various industries, including automotive, robotics, machinery, and more. Their ability to redirect motion and transmit power at right angles makes them versatile for different mechanical systems.

5. Backlash Minimization: Miter gearboxes are designed to minimize backlash through precise tooth profile shaping, gear alignment, and high-quality bearings. This ensures accurate and reliable motion without unwanted play.

6. Specialized Applications: While other gear systems like helical or spur gears offer advantages in certain scenarios, miter gearboxes excel in applications requiring angular transmission, compactness, and efficient power transfer at right angles.

Overall, miter gearboxes stand out for their unique ability to transmit motion at a specific angle and their compact, efficient, and versatile design, making them a valuable choice for a range of mechanical applications.

Proper Installation and Alignment of Miter Gearboxes:

Installing and aligning a miter gearbox correctly is crucial to ensure optimal performance and longevity. Here’s a step-by-step guide on how to do it:

- Preparation: Gather all the necessary tools and equipment for the installation, including mounting hardware, shims, and measuring instruments.

- Positioning: Place the miter gearbox in the desired location, ensuring that it is level and securely supported. Use appropriate mounting brackets or plates to secure the gearbox to the mounting surface.

- Shaft Alignment: Align the input and output shafts of the miter gearbox with the shafts of the connected equipment. Check that the shafts are parallel and collinear for proper alignment.

- Check Tolerance: Measure the axial and radial alignment tolerances between the gearbox and connected equipment. Use precision measuring tools such as dial indicators or laser alignment systems to ensure accurate measurements.

- Adjustment: If alignment tolerances are not within the specified range, make necessary adjustments using shims or other alignment techniques. Gradually add or remove shims as needed to achieve proper alignment.

- Bolt Tightening: Once the miter gearbox is properly aligned, gradually tighten the mounting bolts or fasteners in a crisscross pattern to evenly distribute the load. Use the recommended torque specifications provided by the gearbox manufacturer.

- Lubrication: Apply the recommended lubricant to the gearbox according to the manufacturer’s guidelines. Proper lubrication is essential for minimizing friction and ensuring smooth operation.

- Testing: Before fully operating the system, perform a test run of the miter gearbox to ensure that it operates smoothly and without any abnormal vibrations or noise.

- Final Checks: Double-check the alignment, bolt tightness, and lubrication after the test run. Make any necessary adjustments before putting the system into full operation.

Proper installation and alignment are critical for maximizing the efficiency, reliability, and lifespan of miter gearboxes. Following these steps and consulting the manufacturer’s guidelines will help ensure optimal performance of the gearbox and the entire mechanical system.

Function of Bevel Gears in a Miter Gearbox

Bevel gears in a miter gearbox are responsible for changing the direction of rotational motion between intersecting shafts. They achieve this by utilizing the principle of conical gear teeth. The bevel gears have tapered tooth profiles that allow them to mesh together at a specific angle, typically 90 degrees in the case of a miter gearbox.

When one bevel gear (the driving gear) rotates, its conical teeth engage with the teeth of the other bevel gear (the driven gear) at the desired angle. As a result, the rotational motion is transmitted from the driving gear to the driven gear, causing the output shaft to rotate perpendicular to the input shaft. This change in direction allows the miter gearbox to redirect motion along a different axis, making it suitable for applications where a 90-degree turn is required.

The precise tooth geometry and alignment of the bevel gears ensure smooth and efficient motion transfer, enabling the miter gearbox to effectively transmit torque and power while changing the direction of rotation.

editor by CX 2024-04-16