Product Description

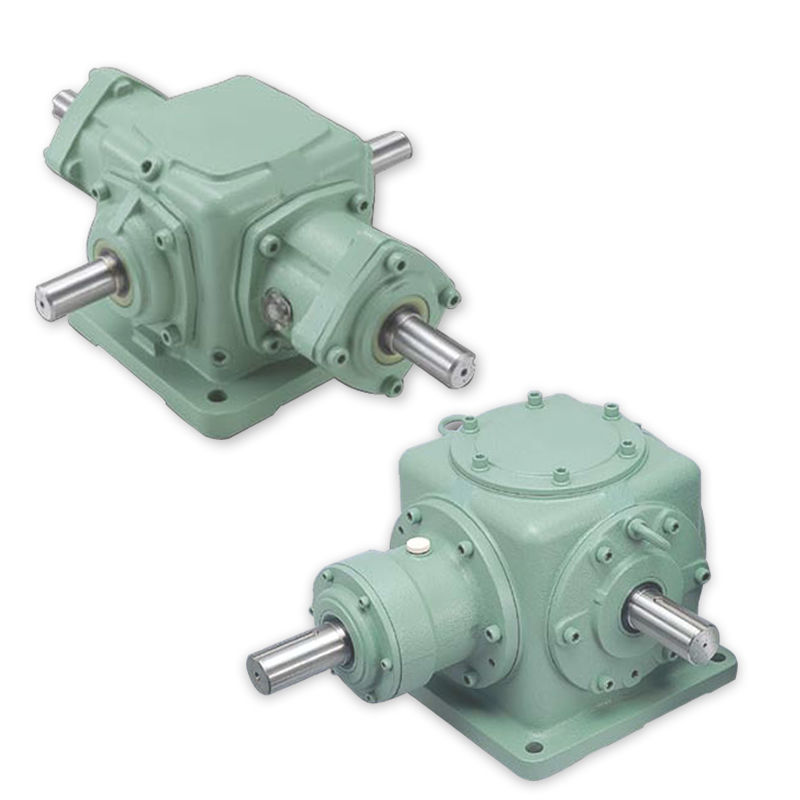

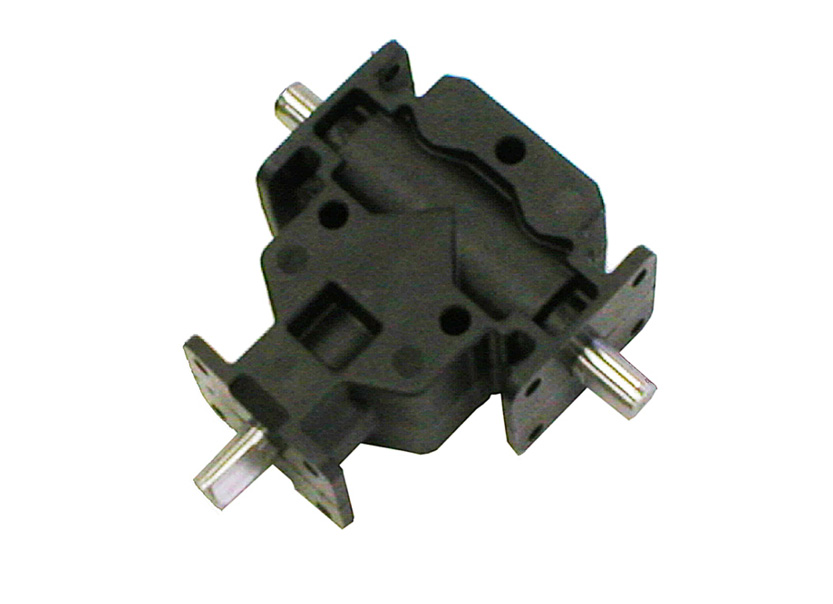

Agricultural gearbox for machinery application 540 pto tractor speed increaser manufacturers suppliers miter bevel rotary mower cutter tiller brush hog mower

Application of Agricultural gearbox

Agricultural gearboxes are used in a wide variety of agricultural equipment, including:

- Tractors: Agricultural gearboxes are used in tractors to transmit power from the engine to the wheels. This allows the tractor to move forward, backward, and turn.

- Combine harvesters: Agricultural gearboxes are used in combine harvesters to transmit power from the engine to the various components of the harvester, such as the header, thresher, and auger. This allows the combine harvester to harvest crops efficiently.

- Plows: Agricultural gearboxes are used in plows to transmit power from the tractor to the plow blade. This allows the plow to turn the soil over and prepare it for planting.

- Sprayers: Agricultural gearboxes are used in sprayers to transmit power from the tractor to the sprayer boom. This allows the sprayer to apply pesticides and fertilizers evenly across a field.

- Harvester heads: Agricultural gearboxes are used in harvester heads to transmit power from the combine harvester to the various components of the head, such as the cutter bar, auger, and thresher. This allows the harvester head to harvest crops efficiently.

Agricultural gearboxes are an essential part of agricultural equipment. They allow agricultural equipment to operate efficiently and effectively, which helps farmers to produce food more efficiently and sustainably.

Here are some of the benefits of using agricultural gearboxes:

- Increased productivity: Agricultural gearboxes can help farmers to increase their productivity by making it easier and faster to complete tasks.

- Reduced costs: Agricultural gearboxes can help farmers to reduce their costs by making it easier to maintain and repair equipment.

- Improved quality: Agricultural gearboxes can help farmers to improve the quality of their products by making it easier to control the production process.

- Increased safety: Agricultural gearboxes can help farmers to increase their safety by making it easier to operate equipment and reduce the risk of accidents.

As you can see, agricultural gearboxes are an important part of agricultural equipment. They offer a number of benefits that can help farmers to produce food and other agricultural products more efficiently, effectively, and safely.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Stepless |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Minimizing Backlash and Ensuring Efficient Power Transfer in Miter Gearboxes

Miter gearboxes are meticulously designed to minimize backlash and ensure efficient power transfer, contributing to smooth and reliable operation in various mechanical systems.

Backlash, the slight movement or play between mating gears, can lead to imprecise motion and reduced accuracy. To address this, miter gearboxes incorporate features such as precision-machined gear teeth, high-quality bearings, and precise alignment of gears and shafts. These design elements help minimize the clearance between gear teeth, reducing or eliminating backlash and ensuring consistent motion transfer.

Efficient power transfer in miter gearboxes is achieved through careful consideration of gear geometry, tooth profiles, and material selection. Engineers optimize gear tooth shapes to minimize friction and maximize contact area between mating gears. Additionally, high-quality materials with appropriate hardness and surface finish are chosen to enhance durability and reduce energy losses due to friction.

The lubrication system also plays a critical role in efficient power transfer. Proper lubrication reduces friction, dissipates heat, and prevents wear, contributing to the overall efficiency of the gearbox.

Overall, the design of miter gearboxes focuses on tight tolerances, precision manufacturing, and thoughtful engineering to minimize backlash and maximize power transfer efficiency, resulting in reliable and high-performance mechanical systems.

Lubrication Requirements for Maintaining Miter Gearbox Efficiency:

Proper lubrication is essential for maintaining the efficiency and longevity of miter gearboxes. Here’s a detailed explanation of the lubrication requirements:

- Selection of Lubricant: Choose a high-quality lubricant specifically designed for gearboxes. The lubricant should have excellent load-carrying capacity, wear resistance, and thermal stability.

- Viscosity: Select the appropriate viscosity grade of lubricant based on the operating conditions, such as temperature and load. The lubricant should maintain its viscosity within the operating temperature range.

- Lubrication Interval: Follow the manufacturer’s recommendations for lubrication intervals. Regularly scheduled lubrication prevents excessive wear and ensures smooth operation.

- Quantity: Use the correct amount of lubricant as specified by the manufacturer. Over- or under-lubrication can affect gearbox performance and lead to premature failure.

- Lubrication Method: Apply the lubricant using the recommended method, such as oil bath, grease, or oil mist lubrication. Ensure that all gear teeth are adequately covered to minimize friction and wear.

- Contaminant Control: Keep the lubrication system clean and free from contaminants. Use proper filtration and sealing to prevent the ingress of dirt, dust, or moisture into the gearbox.

- Monitoring: Regularly monitor the lubricant’s condition through oil analysis or visual inspection. Replace the lubricant if signs of degradation, contamination, or wear are observed.

- Re-lubrication: During maintenance intervals, thoroughly clean the gearbox and replace the old lubricant with fresh lubricant. Ensure proper disposal of used lubricants following environmental regulations.

- Extreme Conditions: In applications with extreme temperatures or heavy loads, consider using lubricants with additives that provide enhanced protection and performance under those conditions.

Adhering to proper lubrication practices ensures that miter gearboxes operate with minimal friction, heat generation, and wear, leading to improved efficiency and extended operational life.

Types of Miter Gearboxes and Their Differences

There are two main types of miter gearboxes: straight miter gearboxes and spiral miter gearboxes.

Straight Miter Gearboxes: In straight miter gearboxes, the bevel gears have teeth that are cut straight across the gear’s face. This design allows for efficient power transmission and is suitable for applications where precise motion redirection is required. However, straight miter gearboxes may produce more noise and vibration due to the nature of the gear tooth engagement.

Spiral Miter Gearboxes: Spiral miter gearboxes use bevel gears with spiral-cut teeth. The spiral angle of the teeth helps to reduce noise and vibration by providing smoother tooth engagement and gradual contact between the gear teeth. This design is especially beneficial for applications where quieter operation and improved durability are desired.

The choice between straight and spiral miter gearboxes depends on the specific requirements of the application, including the desired level of noise, vibration, and efficiency. Both types of miter gearboxes offer the same fundamental motion transmission principle, but the design differences impact their performance characteristics.

editor by CX 2024-01-09