Product Description

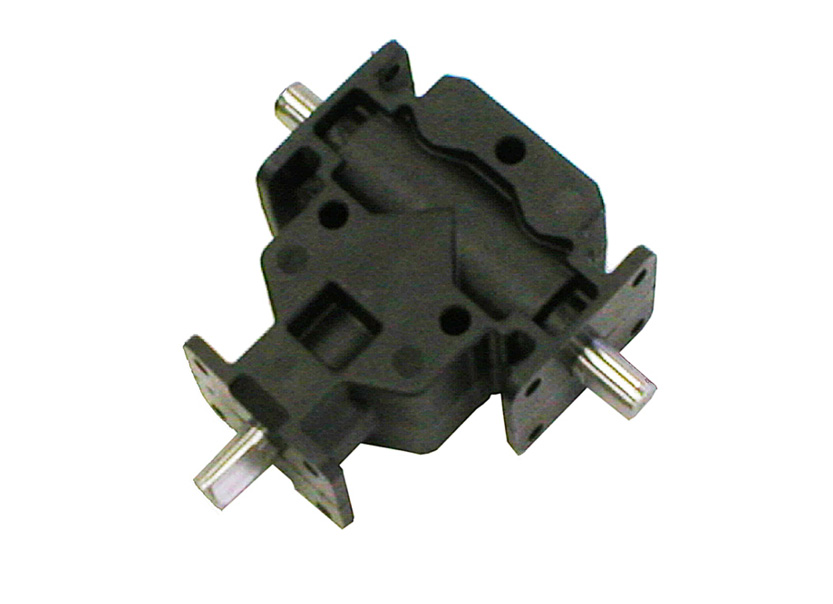

CHINAMFG J40/40 53KW-61KW Used For Boat Ship Marine Engine Gearbox

Product Description

FADA J40/40 53KW-61KW used for china vessel boat ship marine engine gearbox

| 40A Modle | ||

| Feature | Fluid control, price favorable | |

| Housing:SAE 1.2.3 | Flange:111/2″,14″ | |

| L×W×H: | 750×590×720mm | N.W.240kg |

| NOMINAL RATIO | EXACT RATIO | RATE(HP/RPM) |

| 2:01 | 2.066:1 | 0.04 |

| 3:01 | 2.957:1 | 0.04 |

| Recommended engine:YANMAR 6CHLN; BAUDOUIN 4D 106 | ||

| 120B Modle | ||

| Feature | Compact structure, fluid control | |

| Housing:SAE 1 | Flange:14″ | |

| L×W×H: | 720×850×870mm | N.W.360kg |

| Nominal coefficient | Accurate coefficient | Ratio (horsepower/r/m) |

| 2:01 | 2.571:1 | 0.12 |

| 3:01 | 2.815:1 | 0.12 |

| Recommended engine | CUMMINS N-885-M;CAT.3306B SCAC.;DAF DKVD1160M;DETROIT 6V-92TA YANMAR 6HA(M)-HTE | |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Electric Cars, Motorcycle |

|---|---|

| Function: | Change Drive Torque |

| Output Speed: | 2000rpm |

| Gearing Arrangement: | Bevel / Miter |

| Ratio: | 2.07:1 / 2.68:1 / 3.6:1 |

| Input Speed: | 750rpm |

| Customization: |

Available

| Customized Request |

|---|

Common Industries and Applications of Miter Gearboxes

Miter gearboxes are widely used across various industries due to their unique capabilities in transmitting motion at a 90-degree angle. Some common industries and applications include: Automotive (steering systems, robotics, machinery, aerospace, construction equipment, marine, medical equipment). The versatility of miter gearboxes to efficiently change the direction of motion and transmit power at right angles makes them valuable components in various industries where precise motion control and compact design are essential.

Proper Installation and Alignment of Miter Gearboxes:

Installing and aligning a miter gearbox correctly is crucial to ensure optimal performance and longevity. Here’s a step-by-step guide on how to do it:

- Preparation: Gather all the necessary tools and equipment for the installation, including mounting hardware, shims, and measuring instruments.

- Positioning: Place the miter gearbox in the desired location, ensuring that it is level and securely supported. Use appropriate mounting brackets or plates to secure the gearbox to the mounting surface.

- Shaft Alignment: Align the input and output shafts of the miter gearbox with the shafts of the connected equipment. Check that the shafts are parallel and collinear for proper alignment.

- Check Tolerance: Measure the axial and radial alignment tolerances between the gearbox and connected equipment. Use precision measuring tools such as dial indicators or laser alignment systems to ensure accurate measurements.

- Adjustment: If alignment tolerances are not within the specified range, make necessary adjustments using shims or other alignment techniques. Gradually add or remove shims as needed to achieve proper alignment.

- Bolt Tightening: Once the miter gearbox is properly aligned, gradually tighten the mounting bolts or fasteners in a crisscross pattern to evenly distribute the load. Use the recommended torque specifications provided by the gearbox manufacturer.

- Lubrication: Apply the recommended lubricant to the gearbox according to the manufacturer’s guidelines. Proper lubrication is essential for minimizing friction and ensuring smooth operation.

- Testing: Before fully operating the system, perform a test run of the miter gearbox to ensure that it operates smoothly and without any abnormal vibrations or noise.

- Final Checks: Double-check the alignment, bolt tightness, and lubrication after the test run. Make any necessary adjustments before putting the system into full operation.

Proper installation and alignment are critical for maximizing the efficiency, reliability, and lifespan of miter gearboxes. Following these steps and consulting the manufacturer’s guidelines will help ensure optimal performance of the gearbox and the entire mechanical system.

Handling High Torque and Speed Requirements with Miter Gearboxes

Miter gearboxes are versatile mechanical components that can be designed to handle both high torque and speed requirements, making them suitable for a wide range of applications.

The ability of miter gearboxes to handle high torque is determined by factors such as the quality of the gear materials, the precision of gear teeth profiles, and the design of the gearbox itself. Miter gearboxes can be engineered with robust and durable materials, optimized gear tooth profiles, and advanced lubrication systems to ensure effective torque transmission without excessive wear or failure.

Similarly, miter gearboxes can be tailored to accommodate high-speed applications. Proper selection of gear materials, lubrication, and design considerations, such as gear tooth geometry and bearing arrangements, contribute to minimizing friction, heat generation, and wear at elevated speeds.

It’s important to note that while miter gearboxes can handle both high torque and speed, there may be practical limitations based on the specific design, size, and intended use of the gearbox. Engineers and designers carefully assess the torque and speed requirements of the application to ensure that the miter gearbox is appropriately designed and configured for optimal performance and longevity.

editor by CX 2024-05-09