Product Description

Low Zero Backlash Worm Gearbox Efficiency Servo Gear Boxes Reducer Electric Transmission Motor Advance Energy Aerospace Industrial Gearboxes

The low backlash drive units HPCNHS type are available in 4 sizes. Each size includes 2 ratios which are 30:1 and 60:1.

The drive units HPCNHS are built with a minimum backlash which can be adjusted due to the duplex toothing of the gears.

The low backlash drive units are built for medium power transmission.

Worm Gear Units:

The NHS-Range gearboxes is available in 4 model sizes and 2 standard ratios.The gearbox size is identical to the centreline distance.

Low backlash Features :

— Worm gear gyration backlash can be adjusted to less than 1 arc.

— Reducer can be re-adjusted the gap after using .

— Input with coupling : reliable without backlash .

— Output using conical clamping ring couplings : reliable without backlash.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Speed Changing, Speed Reduction |

| Layout: | Wrom |

| Hardness: | Hardened Tooth Surface |

| Installation: | Worm Reducer |

| Step: | Worm Drive |

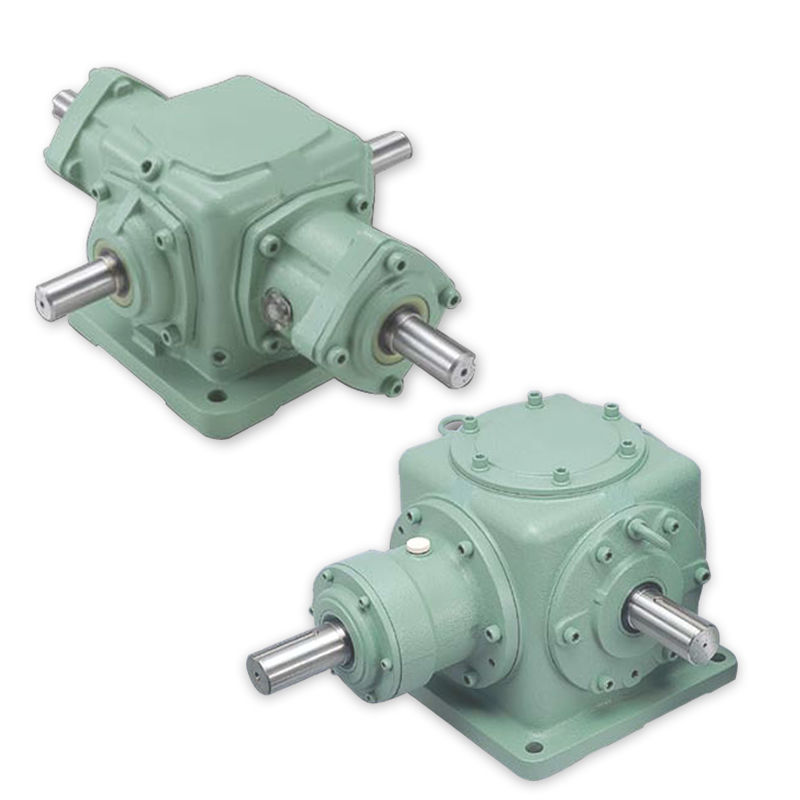

Minimizing Backlash and Ensuring Efficient Power Transfer in Miter Gearboxes

Miter gearboxes are meticulously designed to minimize backlash and ensure efficient power transfer, contributing to smooth and reliable operation in various mechanical systems.

Backlash, the slight movement or play between mating gears, can lead to imprecise motion and reduced accuracy. To address this, miter gearboxes incorporate features such as precision-machined gear teeth, high-quality bearings, and precise alignment of gears and shafts. These design elements help minimize the clearance between gear teeth, reducing or eliminating backlash and ensuring consistent motion transfer.

Efficient power transfer in miter gearboxes is achieved through careful consideration of gear geometry, tooth profiles, and material selection. Engineers optimize gear tooth shapes to minimize friction and maximize contact area between mating gears. Additionally, high-quality materials with appropriate hardness and surface finish are chosen to enhance durability and reduce energy losses due to friction.

The lubrication system also plays a critical role in efficient power transfer. Proper lubrication reduces friction, dissipates heat, and prevents wear, contributing to the overall efficiency of the gearbox.

Overall, the design of miter gearboxes focuses on tight tolerances, precision manufacturing, and thoughtful engineering to minimize backlash and maximize power transfer efficiency, resulting in reliable and high-performance mechanical systems.

Limitations of Torque and Speed in Miter Gearboxes

Miter gearboxes, like any mechanical component, have certain limitations when it comes to handling torque and speed. These limitations are influenced by factors such as design, materials, and manufacturing processes:

- Torque Capacity: The maximum torque that a miter gearbox can handle is determined by the size and strength of the gears, shafts, and housing. Exceeding the rated torque can lead to gear tooth wear, tooth breakage, and even gearbox failure.

- Speed Limitations: The rotational speed of a miter gearbox is limited by factors like the diameter of the gears and the quality of the gear teeth. High speeds can generate heat and cause excessive wear, reducing the lifespan of the gearbox.

- Heat Generation: Excessive torque or speed can lead to increased heat generation due to friction and load. Elevated temperatures can affect the lubrication, material strength, and overall performance of the gearbox.

- Lubrication: Inadequate or improper lubrication can limit the torque and speed capabilities of a miter gearbox. Lubrication helps reduce friction and dissipate heat, enabling the gearbox to handle higher loads and speeds.

- Material Strength: The choice of materials used in the gearbox’s construction influences its torque and speed limitations. High-quality materials with appropriate hardness and tensile strength are essential for withstanding heavy loads and high speeds.

It’s important to carefully consider the specific torque and speed requirements of an application when selecting a miter gearbox. Exceeding the gearbox’s rated limits can result in decreased performance, increased wear and tear, and potential system failures.

Function of Bevel Gears in a Miter Gearbox

Bevel gears in a miter gearbox are responsible for changing the direction of rotational motion between intersecting shafts. They achieve this by utilizing the principle of conical gear teeth. The bevel gears have tapered tooth profiles that allow them to mesh together at a specific angle, typically 90 degrees in the case of a miter gearbox.

When one bevel gear (the driving gear) rotates, its conical teeth engage with the teeth of the other bevel gear (the driven gear) at the desired angle. As a result, the rotational motion is transmitted from the driving gear to the driven gear, causing the output shaft to rotate perpendicular to the input shaft. This change in direction allows the miter gearbox to redirect motion along a different axis, making it suitable for applications where a 90-degree turn is required.

The precise tooth geometry and alignment of the bevel gears ensure smooth and efficient motion transfer, enabling the miter gearbox to effectively transmit torque and power while changing the direction of rotation.

editor by CX 2023-11-27